The Only Guide to American Plastics

Table of ContentsWhat Does American Plastics Do?The Single Strategy To Use For American Plastics4 Simple Techniques For American PlasticsThe smart Trick of American Plastics That Nobody is Talking AboutGetting My American Plastics To WorkAmerican Plastics - Questions

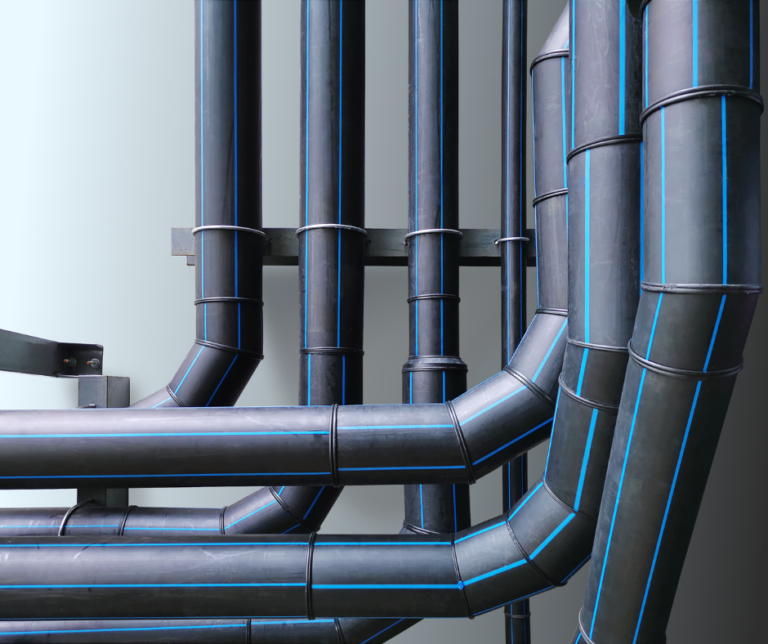

This may include protecting pipelines from extreme temperatures, preventing direct exposure to chemicals or harsh substances, and carrying out correct assistance and anchoring to protect against drooping or movement. Here are responses to some often asked concerns relevant to HDPE pipeline PSI rankings: The optimum PSI ranking for HDPE pipelines can differ depending on factors such as diameter, wall thickness, and material composition.

No, it is not suggested to use a reduced PSI-rated HDPE pipeline for a higher-pressure application. Doing so might lead to pipe failure, leaks, or various other safety threats.

You can verify the PSI ranking of an HDPE pipe by inspecting the producer's paperwork and certification. Trusted producers supply accurate and dependable info concerning the PSI ranking of their pipes.

Innovations in producing strategies enable the manufacturing of HDPE pipelines with thinner walls while preserving the called for PSI ratings. Thinner wall pipelines provide advantages such as boosted flow prices, minimized transport costs, and more efficient installations. New jointing methods and innovations are being developed to improve the stamina and integrity of HDPE pipeline connections.

Top Guidelines Of American Plastics

Keep educated about the current developments in the market to take advantage of the innovations that can better boost your jobs. With this detailed overview available, you are well-appointed to make informed decisions and achieve successful end results. The Great Pyramid of Giza The Hanging Gardens of Babylon No suits were located.

All community water systems include flowing water. For instance, HDPE (PE4710) DR 17 pipe has a fixed stress ranking for water of 125 psig. The functioning stress ranking (WPR) is based on real system demands and is a, that is, a stress score for pipeline with flowing water.

At an everyday reoccuring average circulation surge velocity of 5 fps and at 80oF, the working pressure score of HDPE (PE4710) DR 17 pipe is also125 psig; similarly, the functioning pressure ranking for PVC DR 18 is 120 psig per AWWA C900-07, Equation 4. PE 4710 has a greater working stress score than PVC at these usual problems.

Not known Details About American Plastics

This connects to cost savings in replacement expenses for generations ahead. Yes, HDPE pipe, because of its thickness being somewhat less than water, will float even when packed with water. When it is preferred to make certain flotation of the line, various kinds of collars, saddles, and strap-on flotation protection gadgets are available.

Screw-anchors are a functional option. Whenever possible, an underwater pipeline needs to be set up in a trench with safety crushed rock cover. Refer to Chapter 10 of the PPI Handbook of Polyethylene Pipe, second ed. HDPE pipe's common operating temperature level range is from -40 oF (-400 C) to 140oF (60oC) although some products may be pressure ranked for solution as high as 180oF (82oC).

Consult with the pipe producer for info on applications. The within surface area of HDPE pipe is without any type of roughness which places it in the "smooth pipe" group, a category that results in the most affordable resistance to fluid circulation. For water applications, HDPE pipe's Hazen and Williams C factor for layout is 150 and does not transform in time.

A Biased View of American Plastics

In-depth discussion of this topic can be discovered in Chapter 9 of PPI's Handbook of Polyethylene Pipeline, 2nd ed. Publications browse this site readily available from the pipeline manufacturer might also cover this topic. Yes, pipe bursting has actually proven to be a very useful ways of pipe rehab. The pipeline recovery market has actually embraced "pipe bursting" as the name of the process of fracturing breakable pipelines (e.g., cast iron, clay, and so on) (high quality hdpe pipe).

Preparation of the host pipe to get the HDPE pipe is completed with a cone shaped head in both bursting and splitting procedures. Refer to PPI Handbook of Polyethylene Pipeline, Second ed., Chp 16.

Detailed discussion of this subject can be located in Chapter 9 of PPI's Handbook of Polyethylene Pipeline, second ed. Publications readily available from the pipe producer might likewise cover this subject. Yes, pipe bursting has proven to be a very important methods of pipe rehabilitation. The pipeline rehabilitation industry has actually taken on "pipeline bursting" as the name of the procedure of bursting weak pipes (e - https://www.goodreads.com/user/show/193944320-dane-coffman.g., cast iron, clay, and so on).

Preparation of the host pipeline to obtain the HDPE pipeline is accomplished with a cone shaped head in both rupturing and splitting processes. Refer to PPI Manual of Polyethylene Pipeline, Second ed., Chp 16.

HDPE pipes are field checked and proven to be influence difficult. Hydrocarbons do not break down polyethylene however can diffuse with the wall surface of HDPE pipe in areas of gross contamination.